Exploring the Benefits and Applications of 4130 Seamless Tubing in Construction

4130 seamless tubing is a popular choice in various industrial applications, particularly in the construction and architectural sectors. Composed primarily of chromium and molybdenum, this alloy steel tubing is known for its excellent strength-to-weight ratio, making it ideal for demanding structures and applications. The seamless nature of this tubing means that it is manufactured without any wel

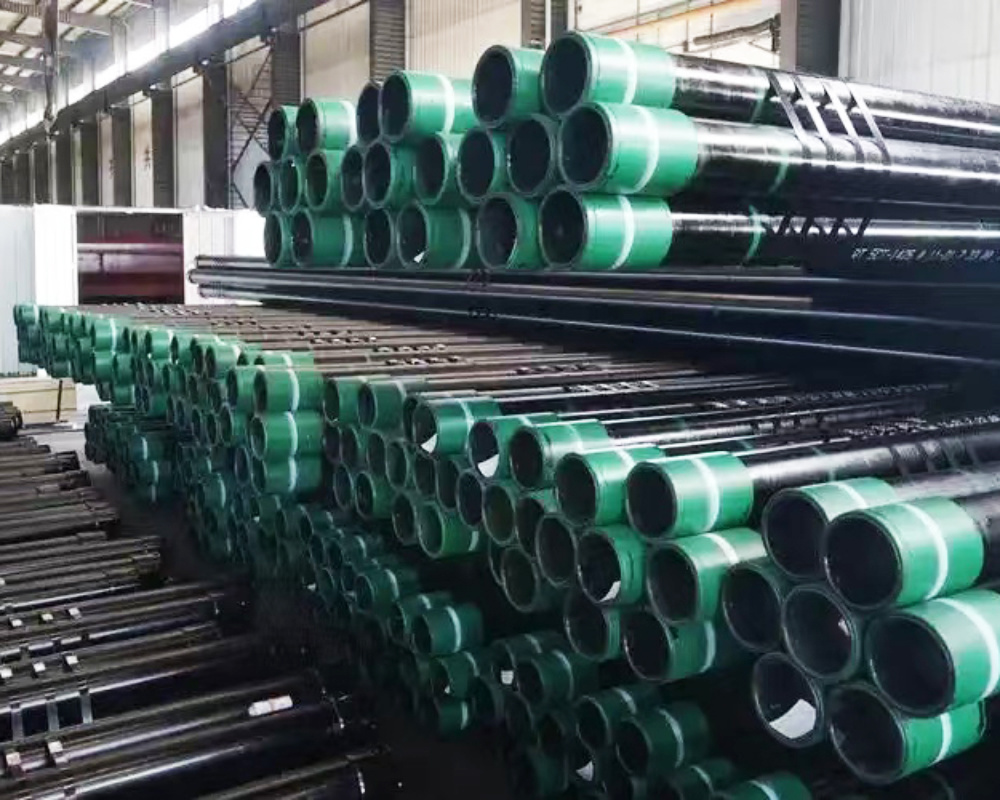

4130 seamless tubing is a popular choice in various industrial applications, particularly in the construction and architectural sectors. Composed primarily of chromium and molybdenum, this alloy steel tubing is known for its excellent strength-to-weight ratio, making it ideal for demanding structures and applications. The seamless nature of this tubing means that it is manufactured without any welds or joints, ensuring higher reliability and resistance to pressure, which is crucial in construction.

One of the primary benefits of 4130 seamless tubing is its high tensile strength. This property is vital in construction, where materials are often subjected to significant loads and stress. The strength of 4130 allows for the reduction of material thickness while maintaining structural integrity, leading to lighter and more efficient designs. This aspect is particularly advantageous in applications where weight-saving is necessary, such as in frames for buildings, bridges, and various structural supports.

Another significant advantage of 4130 seamless tubing is its exceptional machinability and weldability. Unlike some other materials, 4130 can be easily cut, shaped, and welded, making it an attractive option for construction projects that require customized solutions. This versatility allows architects and engineers to implement innovative designs without being constrained by material limitations.

Corrosion resistance is another critical factor that enhances the appeal of 4130 seamless tubing. While not entirely immune to corrosion, the alloying elements in 4130 provide a certain level of protection against atmospheric and environmental factors. This property ensures that the tubing maintains its integrity over time, particularly in outdoor applications or environments with fluctuating weather conditions.

In addition to its mechanical properties, 4130 seamless tubing is commonly used in the manufacturing of various components such as automotive parts, aerospace structures, and oil and gas applications. Its adaptability means that it meets the rigorous demands of these industries while also being a reliable choice for construction projects.

In summary, the advantages of 4130 seamless tubing, including its high strength, machinability, and corrosion resistance, make it an excellent choice for building materials and structural applications. Its seamless design enhances reliability and performance, contributing to the overall safety and durability of construction projects. Understanding these benefits allows architects, engineers, and builders to make informed decisions when selecting materials for their projects, ensuring that they achieve optimal results with superior products.

One of the primary benefits of 4130 seamless tubing is its high tensile strength. This property is vital in construction, where materials are often subjected to significant loads and stress. The strength of 4130 allows for the reduction of material thickness while maintaining structural integrity, leading to lighter and more efficient designs. This aspect is particularly advantageous in applications where weight-saving is necessary, such as in frames for buildings, bridges, and various structural supports.

Another significant advantage of 4130 seamless tubing is its exceptional machinability and weldability. Unlike some other materials, 4130 can be easily cut, shaped, and welded, making it an attractive option for construction projects that require customized solutions. This versatility allows architects and engineers to implement innovative designs without being constrained by material limitations.

Corrosion resistance is another critical factor that enhances the appeal of 4130 seamless tubing. While not entirely immune to corrosion, the alloying elements in 4130 provide a certain level of protection against atmospheric and environmental factors. This property ensures that the tubing maintains its integrity over time, particularly in outdoor applications or environments with fluctuating weather conditions.

In addition to its mechanical properties, 4130 seamless tubing is commonly used in the manufacturing of various components such as automotive parts, aerospace structures, and oil and gas applications. Its adaptability means that it meets the rigorous demands of these industries while also being a reliable choice for construction projects.

In summary, the advantages of 4130 seamless tubing, including its high strength, machinability, and corrosion resistance, make it an excellent choice for building materials and structural applications. Its seamless design enhances reliability and performance, contributing to the overall safety and durability of construction projects. Understanding these benefits allows architects, engineers, and builders to make informed decisions when selecting materials for their projects, ensuring that they achieve optimal results with superior products.

TAG:

Related Posts

Understanding the Manufacturing Process of 4140 Seamless Tubing: A Comprehensive Guide

Understanding the Manufacturing Process of 4140 Seamless Tubing

Table of Contents

1. Introduction to 4140 Seamless Tubing

2. What is 4140 Alloy Steel?

3. The Importance of Seamless Tubing in Modern Applications

4. Overview of the Manufacturing Process for 4140 Seamless Tubing

4.1 Raw Material Procurement

4.2 Heating and Forming

4.3 Pier