Understanding the Manufacturing Process of 4140 Seamless Tubing: A Comprehensive Guide

Understanding the Manufacturing Process of 4140 Seamless Tubing

Table of Contents

1. Introduction to 4140 Seamless Tubing

2. What is 4140 Alloy Steel?

3. The Importance of Seamless Tubing in Modern Applications

4. Overview of the Manufacturing Process for 4140 Seamless Tubing

4.1 Raw Material Procurement

4.2 Heating and Forming

4.3 Pier

Understanding the Manufacturing Process of 4140 Seamless Tubing

Table of Contents

- 1. Introduction to 4140 Seamless Tubing

- 2. What is 4140 Alloy Steel?

- 3. The Importance of Seamless Tubing in Modern Applications

- 4. Overview of the Manufacturing Process for 4140 Seamless Tubing

- 4.1 Raw Material Procurement

- 4.2 Heating and Forming

- 4.3 Piercing Process

- 4.4 Elongation and Sizing

- 4.5 Heat Treatment

- 4.6 Final Inspection and Quality Control

- 5. Common Applications of 4140 Seamless Tubing

- 6. Advantages of Using 4140 Seamless Tubing

- 7. Challenges in Manufacturing 4140 Seamless Tubing

- 8. Conclusion

- FAQs about 4140 Seamless Tubing Manufacturing

1. Introduction to 4140 Seamless Tubing

The manufacturing of **4140 seamless tubing** is a process that brings together metallurgy and advanced engineering techniques. This versatile product is widely used in various industries, including automotive, aerospace, and construction, due to its superior mechanical properties and resistance to wear and fatigue. Understanding how this tubing is manufactured helps stakeholders appreciate its value and application.

2. What is 4140 Alloy Steel?

**4140 alloy steel** is a chromium-molybdenum steel that is known for its toughness, high fatigue strength, and ability to withstand high stress. It contains approximately 0.40% carbon, which gives it a good balance of strength and ductility. The addition of chromium and molybdenum enhances its hardenability and resistance to corrosion. This unique composition makes 4140 ideal for manufacturing seamless tubing that requires both strength and durability.

3. The Importance of Seamless Tubing in Modern Applications

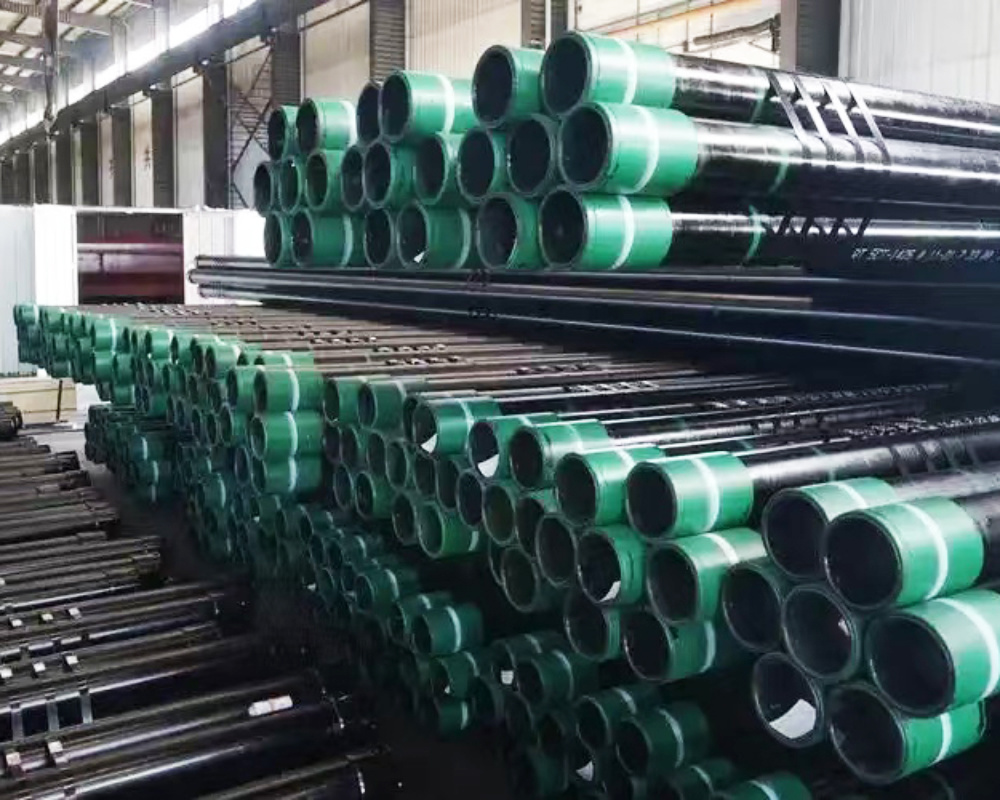

Seamless tubing is preferred over welded tubing in numerous applications owing to its structural integrity and uniformity. In high-pressure environments, such as in gas and oil pipelines, the absence of weld seams minimizes the risk of failure. **Seamless tubes** are also crucial in the automotive industry for parts like axles and suspension components, where the tubing must withstand significant load and stress without compromising performance.

4. Overview of the Manufacturing Process for 4140 Seamless Tubing

The production of 4140 seamless tubing involves several critical steps that ensure the final product meets stringent industry standards. Understanding these steps reveals the complexity and precision involved in manufacturing seamless tubing.

4.1 Raw Material Procurement

The manufacturing process begins with the procurement of high-quality raw materials. The primary material is **4140 alloy steel**, which is sourced from reputable suppliers to ensure consistency in quality. Manufacturers often conduct chemical analysis and mechanical testing on the raw materials to guarantee they meet the required specifications.

4.2 Heating and Forming

Once the raw materials are secured, the steel billets undergo heating in a furnace. The temperature is typically raised to around 2,300°F (1,260°C), allowing the material to reach a malleable state. After heating, the billets are formed into cylindrical shapes using a rotary piercer or a similar device. This initial forming process is crucial for shaping the future seamless tubing.

4.3 Piercing Process

After forming, the heated billets are subjected to a piercing process. This step involves creating a hollow tube by driving a piercing plug through the center of the hot billet. The piercing operation is critical, as it ensures the tube's wall thickness remains consistent, which is essential for maintaining quality and strength.

4.4 Elongation and Sizing

Following the piercing, the tubes undergo elongation, where they are further stretched to achieve the desired length and wall thickness. This process often involves a series of passes through sizing dies, allowing for precise control over the dimensions of the finished product. Maintaining exact specifications is paramount, as even minor deviations can affect performance.

4.5 Heat Treatment

Heat treatment is a vital step in achieving the desired mechanical properties of 4140 seamless tubing. The tubes are subjected to processes such as quenching and tempering. Quenching involves rapidly cooling the tubes in water or oil, which hardens the material. Following this, tempering is performed to relieve internal stresses and improve ductility, ensuring the tubing can withstand operational demands.

4.6 Final Inspection and Quality Control

Before the seamless tubing can be shipped to customers, a rigorous inspection and testing phase takes place. This step includes non-destructive testing methods like ultrasonic and radiographic examinations to detect any internal flaws. Additionally, mechanical testing for yield strength, tensile strength, and elongation is performed to ensure the tubing meets the specified requirements.

5. Common Applications of 4140 Seamless Tubing

The versatility of 4140 seamless tubing is evident in its wide range of applications. Commonly used in:

- **Automotive components** such as axles, spindles, and drive shafts.

- **Oil and gas industries** for pipelines and valves that operate under high pressure.

- **Aerospace applications**, including structural components that require high strength-to-weight ratios.

- **Construction machinery** where durability and resistance to wear are critical.

6. Advantages of Using 4140 Seamless Tubing

Choosing 4140 seamless tubing offers numerous advantages:

- **Mechanical Strength**: The alloy provides high tensile and yield strength, making it ideal for demanding applications.

- **Durability**: The seamless structure minimizes weaknesses that could arise from weld joints.

- **Corrosion Resistance**: The alloy’s chemical composition offers natural resistance to rust and corrosion, extending the lifespan of components.

- **Versatility**: With the ability to manufacture tubing in various sizes and wall thicknesses, 4140 seamless tubing can be tailored to meet specific application requirements.

7. Challenges in Manufacturing 4140 Seamless Tubing

Despite its advantages, the manufacturing process of 4140 seamless tubing is not without challenges. Some common challenges include:

- **Maintaining Consistency**: Ensuring uniform quality across batches requires stringent quality control and testing protocols.

- **Technical Expertise**: The processes involved demand skilled labor and expertise, making workforce training essential.

- **Cost of Production**: The intricate manufacturing processes can lead to higher production costs, affecting pricing in competitive markets.

8. Conclusion

The manufacturing process of **4140 seamless tubing** is a complex interplay of metallurgy and precision engineering. From raw material procurement to final inspection, each step is crucial in producing a product that meets the rigorous demands of various industries. Understanding these processes not only highlights the importance of quality control but also emphasizes the advantages of 4140 seamless tubing in modern applications. As industries continue to evolve, the demand for high-quality, durable materials like 4140 seamless tubing will remain essential.

FAQs about 4140 Seamless Tubing Manufacturing

1. What is the primary use of 4140 seamless tubing?

4140 seamless tubing is commonly used in automotive, aerospace, and oil and gas industries due to its strength and durability.

2. How does heat treatment affect 4140 seamless tubing?

Heat treatment enhances the mechanical properties of 4140 seamless tubing, improving its strength, ductility, and fatigue resistance.

3. What standards are involved in the production of 4140 seamless tubing?

Manufacturers often adhere to standards set by organizations such as ASTM, ensuring quality and performance specifications are met.

4. Can 4140 seamless tubing be welded?

While welding is possible, it is generally not recommended as it can compromise the structural integrity of the tubing.

5. What factors should be considered when selecting seamless tubing for an application?

Considerations include the tubing's mechanical properties, dimensions, compatibility with the environment, and specific application requirements.

By providing a clear understanding of the manufacturing process, applications, and advantages of 4140 seamless tubing, this article aims to serve as a comprehensive resource for professionals in the field.

TAG:

Previous

Related Posts

Understanding the Manufacturing Process of 4140 Seamless Tubing: A Comprehensive Guide

Understanding the Manufacturing Process of 4140 Seamless Tubing

Table of Contents

1. Introduction to 4140 Seamless Tubing

2. What is 4140 Alloy Steel?

3. The Importance of Seamless Tubing in Modern Applications

4. Overview of the Manufacturing Process for 4140 Seamless Tubing

4.1 Raw Material Procurement

4.2 Heating and Forming

4.3 Pier