How Cold Drawn Seamless Tubing Enhances Structural Integrity

How Cold Drawn Seamless Tubing Enhances Structural Integrity

Table of Contents

1. Introduction to Cold Drawn Seamless Tubing

2. What is Cold Drawn Seamless Tubing?

3. Key Benefits of Cold Drawn Seamless Tubing

3.1 Enhanced Strength and Durability

3.2 Improved Corrosion Resistance

3.3 Better Dimensional Tolerances

4. Applications of Cold Dr

How Cold Drawn Seamless Tubing Enhances Structural Integrity

Table of Contents

- 1. Introduction to Cold Drawn Seamless Tubing

- 2. What is Cold Drawn Seamless Tubing?

- 3. Key Benefits of Cold Drawn Seamless Tubing

- 3.1 Enhanced Strength and Durability

- 3.2 Improved Corrosion Resistance

- 3.3 Better Dimensional Tolerances

- 4. Applications of Cold Drawn Seamless Tubing

- 5. The Manufacturing Process of Cold Drawn Seamless Tubing

- 6. Importance of Quality Control

- 7. Future Trends in Cold Drawn Seamless Tubing

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Cold Drawn Seamless Tubing

In the realm of construction and engineering, **structural integrity** is paramount. As structures become more complex and demanding, the materials used must meet exceptional standards of strength and durability. One such material that has gained significant traction is **cold drawn seamless tubing**. This article will explore how this innovative product enhances structural integrity and its importance across multiple industries.

2. What is Cold Drawn Seamless Tubing?

**Cold drawn seamless tubing** is a type of steel tubing manufactured without the use of seams, resulting in a continuous, hollow profile. This manufacturing technique involves drawing the tube through a die at room temperature, which refines its dimensions and improves its mechanical properties. The absence of seams ensures that the tubing can withstand higher pressure and stress, making it an ideal choice for various applications in construction and engineering.

3. Key Benefits of Cold Drawn Seamless Tubing

Cold drawn seamless tubing is prized for several **benefits** that significantly enhance structural integrity.

3.1 Enhanced Strength and Durability

One of the most notable advantages of cold drawn seamless tubing is its **enhanced strength**. The cold drawing process aligns the grain structure of the metal, leading to increased tensile strength and yield strength. As a result, structures utilizing this tubing can bear loads more effectively, reducing the risk of structural failure.

3.2 Improved Corrosion Resistance

Cold drawn seamless tubing is often treated with anti-corrosive coatings or composed of stainless steels that exhibit excellent resistance to corrosion. This property is critical for applications exposed to harsh environmental conditions, such as in marine or industrial settings. By minimizing corrosion, the lifespan of the structures is extended, further enhancing structural integrity.

3.3 Better Dimensional Tolerances

The cold drawing process not only improves the strength of the tubing but also allows for better **dimensional tolerances**. This precision in manufacturing ensures that the tubing fits perfectly into its designated application, which is crucial in construction projects where every measurement matters. Improved tolerances reduce the need for extensive modifications during installation, saving both time and costs.

4. Applications of Cold Drawn Seamless Tubing

Cold drawn seamless tubing finds applications across various sectors, each benefiting from its unique properties.

4.1 In the Construction Industry

In construction, cold drawn seamless tubing is often used for structural supports, frames, and columns. Its high strength-to-weight ratio makes it an excellent choice for high-rise buildings and bridges that demand robust materials capable of bearing substantial loads.

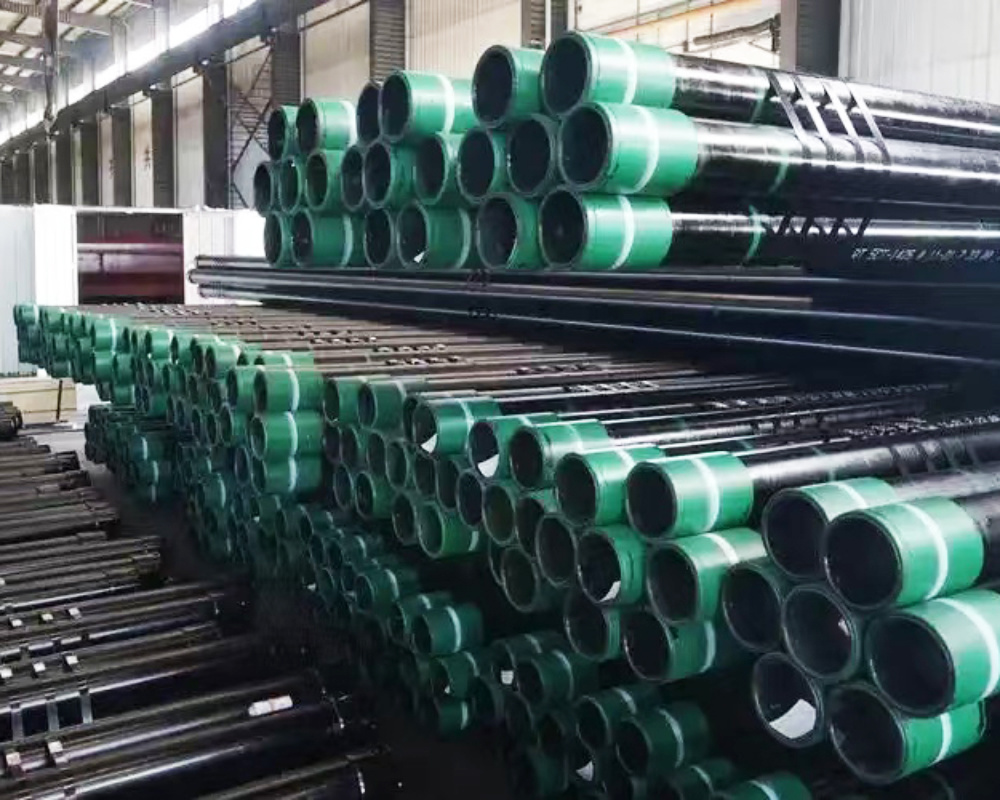

4.2 In the Oil and Gas Sector

The oil and gas industry relies heavily on cold drawn seamless tubing for **pipelines** and other critical components. The tubing's ability to withstand high pressures and resist corrosion is vital in maintaining the integrity of oil and gas transport systems.

4.3 In the Automotive Industry

In the automotive sector, cold drawn seamless tubing is used in the manufacturing of **chassis** and suspension components. Its lightweight yet durable nature allows for enhanced performance and safety in vehicles, contributing to improved fuel efficiency and handling.

5. The Manufacturing Process of Cold Drawn Seamless Tubing

The manufacturing of cold drawn seamless tubing involves several key steps:

1. **Piercing**: A solid round bar is pierced to create a hollow tube.

2. **Extrusion**: The hollow tube is then extruded to the desired length.

3. **Cold Drawing**: The tube is drawn through progressively smaller dies at room temperature, refining its dimensions and enhancing its mechanical properties.

4. **Heat Treatment**: Optional heat treatment may be applied to improve strength and durability further.

5. **Finishing**: The tubing undergoes surface finishing processes to achieve the desired surface quality.

Each of these steps is vital in producing high-quality cold drawn seamless tubing that meets industry standards.

6. Importance of Quality Control

Ensuring the quality of cold drawn seamless tubing is crucial. Rigorous quality control measures throughout the manufacturing process help detect any defects early on. These controls include dimensional inspections, tensile tests, and non-destructive testing techniques. By adhering to strict quality standards, manufacturers can guarantee that their products will perform reliably in demanding applications, ultimately enhancing the structural integrity of the structures they support.

7. Future Trends in Cold Drawn Seamless Tubing

As technology evolves, so do the methods and materials used in manufacturing cold drawn seamless tubing. Future trends may include:

- **Advanced Alloys**: The development of new alloy compositions that further enhance strength and corrosion resistance.

- **Sustainable Manufacturing**: Increasing focus on eco-friendly manufacturing processes and materials.

- **Smart Tubing**: The integration of sensors into tubing to monitor the structural health of installations in real-time.

These advancements will likely lead to even greater applications of cold drawn seamless tubing in the construction and engineering sectors.

8. Frequently Asked Questions

What is the difference between seamless and welded tubing?

Seamless tubing is manufactured without any seams, offering higher strength and reliability. In contrast, welded tubing has a seam where two metal edges are fused together, which can be a point of weakness under high stress.

How does cold drawing improve the mechanical properties of tubing?

Cold drawing elongates the metal and aligns its grain structure, leading to improved tensile strength and yield strength, which enhances the overall performance of the tubing.

What industries use cold drawn seamless tubing?

Cold drawn seamless tubing is widely used in construction, oil and gas, automotive, aerospace, and various industrial applications due to its strength and durability.

Can cold drawn seamless tubing be customized?

Yes, manufacturers can customize cold drawn seamless tubing to meet specific dimensional and material requirements, ensuring it fits the particular needs of various applications.

What are the maintenance requirements for structures using cold drawn seamless tubing?

Regular inspections for corrosion and structural integrity are recommended. Depending on the environment, additional protective coatings may be applied to enhance durability.

9. Conclusion

Cold drawn seamless tubing plays an indispensable role in enhancing **structural integrity** across various industries. Its unique properties, including enhanced strength, improved corrosion resistance, and precise dimensional tolerances, make it a preferred choice for demanding applications. As technology continues to advance, the potential for cold drawn seamless tubing will only grow, further solidifying its importance in modern construction and engineering. Investing in this high-quality material not only ensures the safety and reliability of structures but also paves the way for innovative applications in the future.

TAG:

Related Posts

Understanding the Manufacturing Process of 4140 Seamless Tubing: A Comprehensive Guide

Understanding the Manufacturing Process of 4140 Seamless Tubing

Table of Contents

1. Introduction to 4140 Seamless Tubing

2. What is 4140 Alloy Steel?

3. The Importance of Seamless Tubing in Modern Applications

4. Overview of the Manufacturing Process for 4140 Seamless Tubing

4.1 Raw Material Procurement

4.2 Heating and Forming

4.3 Pier