Why Choose Seamless and Welded Pipes for Your Construction Needs?

Why Choose Seamless and Welded Pipes for Your Construction Needs?

Table of Contents

Introduction to Seamless and Welded Pipes

What Are Seamless Pipes?

What Are Welded Pipes?

Advantages of Seamless Pipes in Construction

Advantages of Welded Pipes in Construction

Applications of Seamless and Welded Pipes

Choosing the Right Pipe for Your Project

Maintenance and Durabi

Why Choose Seamless and Welded Pipes for Your Construction Needs?

Table of Contents

- Introduction to Seamless and Welded Pipes

- What Are Seamless Pipes?

- What Are Welded Pipes?

- Advantages of Seamless Pipes in Construction

- Advantages of Welded Pipes in Construction

- Applications of Seamless and Welded Pipes

- Choosing the Right Pipe for Your Project

- Maintenance and Durability Considerations

- Conclusion

- Frequently Asked Questions (FAQs)

Introduction to Seamless and Welded Pipes

In the construction industry, selecting the right pipes is crucial for ensuring the integrity and longevity of a project. **Seamless and welded pipes** are two of the most commonly used types that serve different functions and offer various advantages. Understanding their characteristics, benefits, and applications can help you make the best choice for your construction needs.

What Are Seamless Pipes?

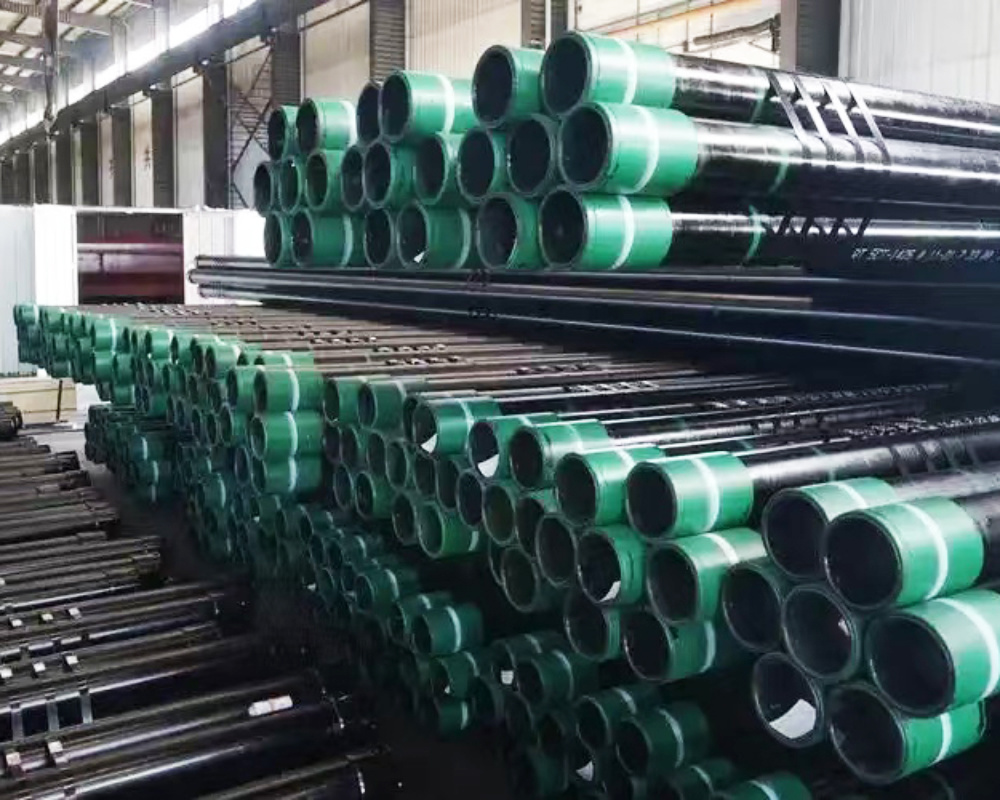

**Seamless pipes** are manufactured from a solid round steel billet, which is heated and pushed or pulled over a form until the steel is shaped into a hollow tube without any seams. This process creates a pipe that has a uniform and consistent structure, making it ideal for high-pressure applications. The absence of seams reduces the risk of failure under pressure, making seamless pipes a preferred option in critical applications.

What Are Welded Pipes?

In contrast, **welded pipes** are produced by rolling steel plates and welding them together to create a pipe. This welding process allows for the creation of large diameter pipes that can be custom-made for various applications. While welded pipes may not offer the same level of strength as seamless pipes in high-pressure scenarios, they are widely used for low-pressure applications and are cost-effective.

Advantages of Seamless Pipes in Construction

Seamless pipes come with a myriad of benefits that make them advantageous for construction professionals:

1. High Strength and Durability

The solid structure of seamless pipes allows them to withstand high pressure and extreme temperatures. Their durability makes them suitable for critical applications, such as oil and gas pipelines and high-rise building construction.

2. Corrosion Resistance

Seamless pipes can be manufactured with materials that enhance their resistance to corrosion, making them suitable for environments exposed to moisture and chemicals. This characteristic ensures a longer lifespan and reduces maintenance costs.

3. Consistent Quality

Since seamless pipes are produced without seams, they present a uniform quality throughout the length of the pipe. This consistency ensures that they perform reliably under varying conditions.

4. Reduced Risk of Leaks

The lack of seams in the design minimizes the potential for leaks, which is crucial in applications where fluid containment is vital. This reliability enhances the safety of construction projects.

Advantages of Welded Pipes in Construction

While seamless pipes have their strengths, **welded pipes** also offer unique advantages that make them suitable for specific applications:

1. Cost-Effectiveness

Welded pipes are typically cheaper to produce than seamless pipes due to the manufacturing process. This cost-effectiveness makes them an attractive option for budget-conscious projects.

2. Versatility

Welded pipes can be manufactured in a variety of sizes and thicknesses, allowing for customization according to project requirements. This flexibility makes them suitable for several applications, including plumbing and HVAC systems.

3. Simplified Repairs

In the event of damage, welded pipes are easier to repair. The welding process allows for patching and modifications without the need for complete replacements.

4. Availability

Welded pipes are widely available and can be sourced from numerous manufacturers, making them a convenient choice for construction projects that require quick procurement.

Applications of Seamless and Welded Pipes

Both seamless and welded pipes find applications across various sectors in construction:

1. Oil and Gas Industry

Seamless pipes are extensively used in oil and gas pipelines due to their high strength and resistance to pressure and temperature variations. Conversely, welded pipes are often utilized for low-pressure applications in this sector.

2. Water Supply Systems

Welded pipes are commonly used in water supply systems due to their easy installation and cost-effectiveness. They are also used in wastewater management systems.

3. Structural Applications

Seamless pipes are often used in structural applications, such as scaffolding, where strength and reliability are paramount.

4. HVAC Systems

Both types of pipes are employed in HVAC systems. Welded pipes are often used in ductwork, while seamless pipes may be utilized in high-efficiency heating and cooling systems.

Choosing the Right Pipe for Your Project

Selecting the appropriate type of pipe depends on several factors, including:

1. Project Requirements

Consider the specific requirements of your project, such as pressure ratings, temperature ranges, and the nature of the fluids being transported. Seamless pipes are ideal for high-pressure applications, while welded pipes are suitable for lower-pressure scenarios.

2. Budget Considerations

Evaluate your budget constraints. If cost is a significant factor, welded pipes may offer the best value while still meeting project specifications.

3. Availability and Lead Time

Consider the availability of the pipes. Depending on your location, one type may be more readily available than the other, which could impact project timelines.

4. Long-Term Performance

Think about the long-term performance and maintenance needs of the pipe. If durability and resistance to leaks are critical, seamless pipes may be the better choice.

Maintenance and Durability Considerations

Proper maintenance is essential to ensure the longevity of both seamless and welded pipes. Regular inspections, cleaning, and addressing any signs of wear or corrosion will help prevent costly repairs and system failures. Understanding the material properties of the pipes used in your project will guide effective maintenance practices.

Conclusion

In summary, choosing between seamless and welded pipes depends on various factors, including your project’s specifications, budget, and long-term performance expectations. Seamless pipes offer unparalleled strength and reliability, making them suited for high-pressure applications, while welded pipes provide versatility and cost-effectiveness for a range of construction needs. By understanding the advantages and applications of each type, you can make an informed decision that best aligns with your construction requirements.

Frequently Asked Questions (FAQs)

1. What is the main difference between seamless and welded pipes?

The primary difference lies in their manufacturing processes. Seamless pipes are made from solid steel billets and do not have seams, while welded pipes are created by rolling and welding steel plates.

2. Which type of pipe is better for high-pressure applications?

Seamless pipes are generally considered superior for high-pressure applications due to their lack of seams, which reduces the risk of failures.

3. Are welded pipes more affordable than seamless pipes?

Yes, welded pipes are typically more cost-effective and can be custom-manufactured in various sizes, making them suitable for budget-sensitive projects.

4. Can seamless pipes be repaired if damaged?

While seamless pipes can be repaired, the process may be more complicated than for welded pipes, which can often be patched easily.

5. What materials are used in the production of seamless and welded pipes?

Both types of pipes can be made from a variety of materials, including carbon steel, stainless steel, and alloy steel, depending on the intended application and environmental conditions.

In making a decision about the types of pipes to use in construction, it is vital to understand their unique characteristics and how they align with your project's specific needs.

TAG:

Previous

Previous:

Related Posts

Understanding the Manufacturing Process of 4140 Seamless Tubing: A Comprehensive Guide

Understanding the Manufacturing Process of 4140 Seamless Tubing

Table of Contents

1. Introduction to 4140 Seamless Tubing

2. What is 4140 Alloy Steel?

3. The Importance of Seamless Tubing in Modern Applications

4. Overview of the Manufacturing Process for 4140 Seamless Tubing

4.1 Raw Material Procurement

4.2 Heating and Forming

4.3 Pier